Logistics is the key element of the SC process and it comprises planning, controlling, organizing, and managing the movement of products and goods from the point of origin to consumption. Inbound logistics outlines the method of sourcing, receiving, and keeping material in the inventory required for production and manufacturing. Today, we’ll discuss the inbound logistics in supply chain management; its process, advantages, and disadvantages.

What is Inbound Logistics in Supply Chain Management?

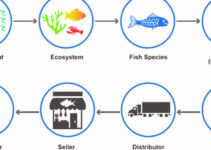

Inbound logistics in SCM is the practice of receiving and keeping the required material for production and manufacturing. It comprises planning and organizing the movement of goods and materials from supplier to warehouse and the production or manufacturing unit. The inbound logistics in SCM comprise the following activities;

- Sourcing and finding

- Purchasing and procurement

- Logistics and transportation

- Storing

The inbounding process starts with finding the source of raw material for production, negotiating the price, and signing the purchasing contract. After recognizing the source of the raw material, next you should organize the transportation from the supplier to a warehouse or the production unit. Here you should coordinate and collaborate with logistics providers, customs brokers, and freight carriers to make sure the safe and timely delivery of the product.

Process of Inbound Logistics in SCM – Activities

The process of inbound logistics in supply chain management comprises of following activities;

Finding & Sourcing

It is the practice of finding, recognizing, and choosing the supplier that offers you the material or component that you need for manufacturing and production. It also comprises negotiating the price and getting a reliable delivery service.

Procurement

Procurement and purchasing in bulk quantity is a formal process and it comprises of discussing the terms and conditions with the supplier like payment method, scheduling, delivery timing, and pricing.

Transportation

As the name implies, it is the method of transporting goods and materials from supplier to warehouse and manufacturing unit. For the cost-efficient and timely delivery of products, it is significant that you should collaborate with the following parties;

- Logistics providers

- Customs brokers

- Freight carrier

Storage

Storing and organizing the material allow you to retrieve the material for production whenever you need it. Storage in the warehouse comprises of following activities;

- Employing store equipment like shelving and pallet racks

- Launching an inventory management system

- Tracking the movement of inventory

Inventory Management

Here you track the flow of goods and materials to make sure that you have got sufficient quantity available in order to meet and satisfy the manufacturing needs. However, it comprises of following;

- Applying an inventory control system

- Establishing reorder limits

- Monitoring inventory level to avoid excess or shortage

Quality Control

You have to make sure the safety and quality standards before implementing anything in the production process. It comprises analyzing the material on receipt and verifying it with the industry standards.

Advantages of Inbound Logistics in SCM

Some of the main advantages and benefits of inbound logistics in supply chain management are as follows;

Better Quality

It is necessary to have an effective inbounding logistics process to make sure the quality of materials and goods. Companies should make sure that their products have the highest quality in order to satisfy the needs and wishes of customers. In fact, it helps businesses and organizations to recognize potential risks and quality issues before their negative impact on the company.

High transparency

Inbounding logistics amplifies visibility and transparency across the SC processes. Companies could easily comprehend their SC processes and recognize potential inefficiencies and problems. They do so by accurately tracking and managing inventory and the flow of material. It improves the decision-making process and quickly reacts to the change in demand and supply.

Competitiveness

Well-optimized inbounding logistics help companies to reduce costs and improve efficiency in SC processes. It amplifies their competitiveness and profitability. Resultantly, you would have a better relationship with the supplier and high customer satisfaction level.

Better Efficiency

Companies could make sure that they have got sufficient resources to satisfy the needs and wishes of customers; they do so by coordinating the flow of material inside the organization. Efficient inbounding logistics would help companies to decrease their lead time, increase competitiveness, and high customer satisfaction levels.

Low Cost

Inbounding logistics decrease their cost by optimizing SC resources and carefully managing various logistical stages. It helps companies to reduce their cost by speeding up rush orders and the shipping process.

Disadvantages of Inbound Logistics in SCM

Some of the key disadvantages and challenges to inbound logistics in supply chain management are as follows;

Quality Issues

Poor quality would result in the form of jeopardizing the reputation of the company and decreasing the customer satisfaction level. It is difficult for companies to make sure the quality of material in the logistical operations.

Capacity Restrictions

If a company has a limited storage and production capacity, then it would impact its capability to deal with logistics efficiently. It results in the form of delays in production and requires the company to invest in equipment and facilities.

Supply & Demand Balance

It is difficult to maintain a balance between the supply of raw materials and the demand for finished goods. It becomes even more difficult when the demand is changing and uncertainty about the supply of raw materials.

Information Issues

When there is limited transparency in the movement and flow of goods and materials, then it is difficult to recognize the potential problems and track performance. It requires more communication between logistics providers, suppliers, and the company.

Inefficient Shipping

Disruption or delay in the transportation of goods decreases production efficiency and increases costs. It happens due to bad weather or crowded traffic.

Conclusion: Inbound Logistics in Supply Chain Management

After an in-depth study of inbound logistics in supply chain management; we have realized that inbound logistics is highly significant for a company’s efficiency. If you are learning about inbounding logistics in SCM, then you should keep in mind the abovementioned process, advantages, and disadvantages.

Ahsan is an accomplished researcher and has a deep insight in worldly life affairs. He goes Live 3 days a week on various social media platforms. Other than research writing, he’s a very interesting person.