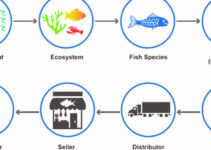

SCM plays a significant role in the growth of businesses and companies by making sure that you deliver the right products and services efficiently to the customers. Innovation in SCM processes has become highly significant in today’s fast-evolving world of internet and technology. Integration of new and latest technology has allowed businesses and companies to achieve better results, decrease costs, and streamline their operations. Today, we’ll discuss innovation in supply chain management; its definition, and top examples.

What is Innovation in SCM?

Innovation in supply chain management focuses on providing the best raw materials and supplies, efficient production and manufacturing processes, and delivering the final product to the end consumers. That’s why it is simple and easy to consider that innovative SCM is much superior to traditional ordinary SCM. Businesses and companies should collaborate with vendors and suppliers to innovate better and safer methods and practices; it allows them to produce and deliver better products and services.

Examples of Innovation in Supply Chain Management

Some of the top examples of innovation in supply chain management are as follows;

Green Supply Chain

Green SCM is the latest emerging concept and it focuses on decreasing the impact of SC operations on the environment and finding sustainable methods of production. The green SCM strategies help you to decrease carbon emission rate, conservation of resources, and reduce waste. However, it is not only beneficial to the environment but also amplifies efficiency, and productivity, and decreases overall cost.

Example – Unilever

Unilever is employing and implementing green SCM strategies and practices to decrease the carbon footprint, but also amplifying customer loyalty and decreasing overall cost.

Drones & Autonomous Vehicles

In order to amplify transportation and logistics efficiency in the SCM processes, businesses and companies employ drones and autonomous vehicles. It allows them to decrease the required time and cost of transportation; so that they could decrease negative environmental impact and improve safety. However, companies employ drones to efficiently deliver products to customers, especially in far-off distant hard-to-reach locations.

Example – Amazon

Amazon employs drones and autonomous vehicles to efficiently deliver product packages to customers. Ultimately, it decreases the time and cost of transportation.

Network & Collaborative Platform

In order to improve communication and collaboration among businesses and their suppliers and vendors; companies employ networks and collaborative platforms in their SC processes. It allows businesses and companies to coordinate and share information with one another, and quickly respond to market changes. You could employ the SC network to amplify efficiency, SC visibility, and transparency, and decrease lead time.

Example – Walmart

Walmart employs networks and collaborative platforms to develop better communication channels with its suppliers and vendors. It results in the form of increasing on-shelf availability and a decrease in stock-outs.

Big Data & Predictive Analytics

Businesses and companies employ big data and predictive analytical tools in their SCM processes to gain a better insight into consumer behavior, optimize their inventory, and forecast future demand. It allows them to recognize patterns and trends by processing vast amounts of data and information; it helps them to make better-informed decisions.

Example – Proctor & Gamble

P&G employs big data and predictive analysis to amplify and improve its inventory level, and it results in the form of increasing on-shelf availability and decreasing stock-outs.

Virtual Reality & Augmented Reality

In order to achieve better quality control, maintenance, and amplify training; companies employ VR (virtual reality) and AR (augmented reality). It allows companies to finish tasks and activities accurately and efficiently by providing instruction to employees and getting information in real-time. However, it helps employees polish and improve their skills and expertise in a controlled and safe environment.

Example – DHL

Delivery service providing company DHL employs AR to guide their employees and warehouses via a complicated picking process, and it significantly amplifies the accuracy and productivity.

Automation & Robotics

Companies employ automation and robotics technology in their SC processes to decrease cost, improve efficiency, and streamline their warehousing operations. It helps them to automate their labor-intensive repetitive processes, the free labor could focus on other complicated tasks. However, it allows them to improve safety, and efficiency, and decrease errors.

Example – Amazon

Amazon employs robotics and automation technology in performing its warehousing operations; it results in the form of improving customer satisfaction and decreasing delivery time.

Additive Manufacturing & 3D Printing

Additive manufacturing and 3D printing help you to decrease the need for traditional supply chains and improve the capability of on-demand production. Companies could decrease the need for storage space and inventory costs by producing goods on demand. It allows companies to improve flexibility and decrease costs.

Example – Adidas

Sportswear manufacturing brand Adidas employs 3D printing machines to produce customized and personalized design shoes for customers. It amplifies customer satisfaction and decreases the need for a tranditional supply chain.

IoT (Internet of Things

IoT has helped businesses and companies transform their SC processes by helping them to analyze and track goods throughout the SC process. You could embed the IoT devices in various products; it helps you to track variables, temperature, and locations. It allows them to optimize their warehousing and logistics operations by improving efficiency and decreasing waste.

Example – DHL

DHL employs IOT devices to track the temperature and location of medical supplies by making sure that they reach the clinics and hospitals safely and on time.

Blockchain Technology

Blockchain technology has revolutionized the SCM processes by improving security, traceability, visibility, and transparency. It allows businesses and companies to develop a decentralized ledger that would help them to maintain a record of transactions in the SC processes from sourcing to delivering the finish goods to the end consumers.

Example – IBM

The food trust platforms of IBM employ blockchain technology to track goods from the farmhouse to the store. It makes sure the food standards and safety measures so that it doesn’t carry any risk of food poison.

Machine Learning & Artificial Intelligence

Businesses and companies employ ML and AI technology in their SC processes for inventory optimization, forecasting demand, and predictive analysis. AI allows you to decrease cost, optimize inventory levels, predict demand, recognize trends, and better comprehension of customer trends. On the other hand, ML helps you to find anomalies and recognize patterns to take preventive measures before they come up.

Example – Walmart

Walmart employs AI and ML technology to deal with its warehouse and inventory level, and it results in the form of improving customer satisfaction levels and limited waste.

Conclusion: Innovation in Supply Chain Management

After an in-depth study of innovation in supply chain management; we have realized that innovative SCM helps you to achieve efficiency and productivity. If you are learning about innovation in SCM, then you should keep in mind the abovementioned examples.

Ahsan is an accomplished researcher and has a deep insight in worldly life affairs. He goes Live 3 days a week on various social media platforms. Other than research writing, he’s a very interesting person.