Stock control or inventory control plays a key role in making sure that the company has sufficient stock to satisfy customer demands and amplify its performance. It deals with various areas like customer satisfaction, shipping, storage, and procurement. Efficient and effective inventory control management would help you to avoid various issues like stocks. Today, we’ll discuss the top 10 inventory control strategies; their definitions; various benefits, and top 10 strategies.

What is Inventory Control?

Inventory control is the method of making sure the availability of the right amount of supply to the company. It helps companies to satisfy customer orders with proper production control and delivers financial flexibility. However, successful inventory control needs data from various sources like; turnover, loss prevention, customer satisfaction, receiving, storage, warehousing, shipping, reorders, and procuring.

Inventory controlling allows companies to amplify their profitability by investing limited resources in inventory without jeopardizing the customer satisfaction level. It helps companies to analyze their existing state relevant to financial reports, account balances, and assets; so that they could avoid stockouts.

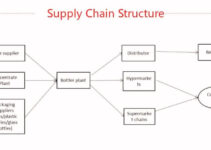

In fact, inventory controlling is the key element of supply chain management; because it deals with the flow of goods, raw supplies, and until the point when they reach the end consumers. Warehouse management falls under the category of stock controlling and it focuses on synchronizing sales and procurement.

Inventory Control vs. Inventory Management

Inventory control and inventory management may seem the same and used interchangeably, but they are completely different. The Inventory Management is the complete process of purchasing, organizing, storing, and earning profit from the products and goods. However, Inventory controlling only focuses on regulating the stock already available in the warehouse.

Benefits of Inventory Control

Some of the main benefits of inventory control strategies are as follows;

Working Capital

Inventory comprises a major area of the working capital of any product or good-based company. If you study the balance sheet, then you will find that a vast portion of your capital resources and assets are stuck in the working capital.

Saving Cost

Inventory controlling allows you to maintain a balance between procuring too much inventory and going without inventory. Companies carry a small inventory with a just-in-time approach. Managing and controlling the right inventory would help them to save capital resources.

Optimization

A company would have the availability of funds with limited inventory. If the company requires higher inventory, then it would increase its sales and profitability. However, inventory control allows them to optimize their supply chain, stock room, and warehouse management.

Top 10 Inventory Control Strategies

Let’s discuss the top 10 inventory control strategies and they’re as follows;

Forecasting

Forecasting and selective inventory control management is a form of analytical approach, that allows you to categorize your inventory based on the following areas;

- Consumption rate

- Unit price

- Seasonality

- Procurement issues

- Procurement source

- Usage value

It is significant to select the right formula based on the categorization and significance and how it would impact your stock.

Regular Audit

Regular auditing would help you to make sure that your reports and actual stock are relevant and streamlined. You can perform an audit in three ways;

- Physical goods: counting and checking inventory physically at the end of the year

- Spot checking: checking a few products from the entire inventory

- Cycle checking: physically checking it and comparing it with the document or software

Risk Analysis

Various types of issues come up in the business; performing the risk analysis would help you to know the worst risk elements, and how you should address them when they come up.

- Discontinued products

- Slow-moving products

- Inventory miscalculation

- Limited warehousing space

- Cash shortfall

- Unexpected sales spike

Automated Reports

Inventory controlling system generates a mass volume of data, and companies should analyze, report, and utilize this data. Many controlling systems automatically deliver reports about inventory financials, aging inventory, historical stock, reconciliation, stock logs, and inventory status.

Supplier Relationship

Supplier relationship plays a key role because it allows you to address problems heads on and solve them by collaborating with the suppliers. Suppliers could offer you a negotiable minimum order quantity; return the products that aren’t selling and restock the warehouse to amplify the sale.

Optimized Methods & Procedures

Proper inventory management would make sure that you employ the right data and forecasting tools to control your procurement procedures. It comprises of following elements;

- Recognizing and analyzing customer demands

- Removing outdated stock

- Making adjustments in the reorder and safety points

Selecting Improvement Strategy

Managing improvement strategies comprises much more than inventory control. You improve your management processes and systems with any of the strategies like lean, Six Sigma, kaizan, or any other.

Material Requirement Planning

It comprises employing computer software or applications to manage your inventory processes. The success and productivity of the inventory outlines segmenting the inventory processes into periodic planning. It would ensure the smooth running of all the operations and processes.

Economic Order Quantity Model

There is a consistency in the customer demand and the inventory would reduce at a fixed rate until it reaches the zero point. It focuses on avoiding shortages and overstocking of the products.

Batch Tracking

You can track the inventory by tracking batch numbers to amplify the efficiency and effectiveness. It tells you the stock is coming from and where it would go; the shipping quantity and when it would expire at the particular time.

Conclusion: Inventory Control Strategies

After an in-depth study of the inventory control strategies; we have realized that inventory controlling plays a key role in the effective supply chain and warehousing processes. If you are learning about the practices for inventory control, then you should keep in mind the abovementioned strategies and benefits.

Ahsan is an accomplished researcher and has a deep insight in worldly life affairs. He goes Live 3 days a week on various social media platforms. Other than research writing, he’s a very interesting person.